Integrated Circuits

Overview

Integrated circuits (ICs) are semiconductor devices that contain one or more active electronic components such as transistors, diodes, resistors, capacitors, inductors, and passive components like resistors, capacitors, inductors, and transformers, all fabricated onto a single chip of semiconductor material, typically silicon. This technology revolutionized electronics by allowing billions of tiny transistors to be packed into an incredibly small space, leading to smaller, faster, cheaper, and more reliable electronic devices.

History

The concept of integrating electronic components dates back to the 1950s when Jack Kilby invented the first integrated circuit. However, it wasn't until the 1960s that the modern integrated circuit was born. The development of microprocessors in the 1970s further accelerated the growth of the IC industry.

Key Components

Transistors

Transistors are the fundamental building block of modern electronics. They act as amplifiers, switches, and voltage regulators. There are two main types of transistors:

- Bipolar Junction Transistor (BJT)

- Field-Effect Transistor (FET)

BJT Structure

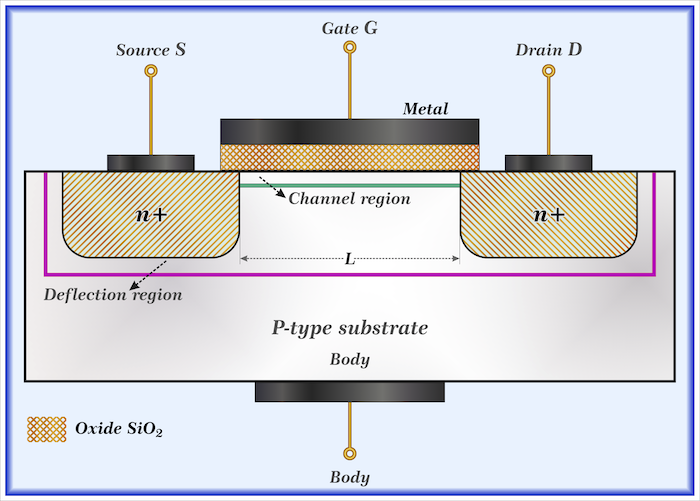

FET Structure

Diodes

Diodes are semiconductor devices that allow current flow in only one direction. They are crucial for rectification and protection against reverse polarity.

Capacitors

Capacitors store electrical energy in an electric field. They are used for filtering, coupling, and storing charge.

Resistors

Resistors control the amount of current flowing through a circuit. They are essential for voltage division, current limiting, and impedance matching.

IC Fabrication Process

The process of fabricating an integrated circuit involves several steps:

-

Wafer Preparation

- Silicon wafers are cut from large ingots

- Wafers are cleaned and polished

-

Oxidation

- A thin layer of silicon dioxide is grown on the wafer surface

-

Photolithography

- Photoresist is applied to the wafer

- Light exposure creates patterns on the photoresist

- The pattern is transferred to the underlying layers

-

Etching

- Chemical etching removes unwanted material based on the photolithography pattern

-

Deposition

- Various materials are deposited onto the wafer surface

-

Planarization

- Techniques like chemical mechanical polishing (CMP) are used to flatten the wafer surface

-

Doping

- Regions of the wafer are selectively altered to change their electrical properties

-

Metallization

- Metal interconnects are added to connect different components

-

Testing

- Individual dies are tested before packaging

-

Packaging

- Dies are mounted onto lead frames or directly onto printed circuit boards

Advanced Topics

Quantum Computing and Neuromorphic Chips

Modern research is exploring the integration of quantum computing principles and neuromorphic architectures into traditional IC designs. These advancements promise significant improvements in computational power and efficiency.

Flexible Electronics

Flexible ICs are being developed for applications in wearable technology, medical devices, and flexible displays.

3D Integration

As Moore's Law continues to face challenges, researchers are exploring three-dimensional integration techniques to increase transistor density while maintaining performance.

Applications

Integrated circuits have revolutionized numerous industries:

- Consumer Electronics

- Automotive Systems

- Medical Devices

- Aerospace and Defense

- Industrial Automation

- Telecommunications

Conclusion

Understanding integrated circuits is crucial for anyone pursuing a career in electronics engineering, computer science, or related fields. As technology continues to advance, the importance of mastering IC design and fabrication will only grow. Whether you're interested in developing cutting-edge processors, designing efficient memory systems, or creating innovative sensors, knowledge of integrated circuits is essential.

Remember, the world of ICs i constantly evolving. Stay curious, keep learning, and watch the boundaries between hardware and software continue to blur!

Now, let's create a separate page for the specific IC fabrication process mentioned in the context:

markdown